What is Sodium Carbonate or Soda Ash

Sodium carbonate is a white crystalline solid that is also known as disodium carbonate or soda ash. It is a member of the chlor-alkali chemical family and competes with caustic soda as a source of alkali (sodium oxide) in many processes. Commercial soda ash is highly purified and is sold in various grades that differ primarily in bulk density.

Uses of Sodium Carbonate

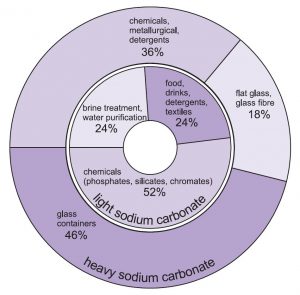

Two forms of sodium carbonate (soda ash) are used – heavy and light. The light form is obtained first and some is then converted into the heavy form. Light sodium carbonate contains less than 0.5% sodium chloride. Heavy sodium carbonate is obtained by hydrating light sodium carbonate to the monohydrate (Na2 CO3 H2O) and then dehydrating it to give a product with an increased crystal size and density.

The two grades have different uses.

The major uses of heavy sodium carbonate are as a solid, particularly in making glass, where it is used as a flux in the melting of silica (sand).

The uses for light sodium carbonate are traditionally where the chemical is required in solution.

Overall, about 50% of the total production of sodium carbonate is used to make glass, 18% to make other chemicals and 10% in soaps and detergents.

Annual production of Sodium Carbonate

| World | 50 million tons |

| Europe | 10 million tons |

| US | 11 million tons |

| Russia | 0,71 million tons |

Transport is generally conducted by chartered vessels, tilt cistern trucks and in big bags on pallets.

Sodium Carbonate demands complicated handling due to the products cohesive characteristics.

Transport of Sodium Carbonate

The total quantity of transport involving Sodium Carbonate is mainly conducted in bulk form in cistern trucks, chartered ship holds and in big bags on pallets.

These transport modes are usually expensive or very reliant on facilities in loading and unloading ports as well as continual transfers of the merchandise from different modes of transport. As the Sodium Carbonate is transferred several times from transport modes, this complicates the transport process and the responsibility of the different operators in these processes in case the Sodium Carbonate has been effected by humidity due to condensation or other factors.

- Several different operators transferring the product from different modes of transport.

- Humidity sensitive Soda Ash

- Special facilities needed in the ports of loading and unloading.

- Transferring Sodium Carbonate into big bags and back into silos at the importers facilities is not cost effecitive

- High packaging costs of big bags + pallet.

- Tilt bulk cisterns are an expensive transport unit.

- Tilting in certain areas is dangerous due to strong winds in many countries.

- Relying on gravity for unloading cohesive bulk-solids such as Sodium Carbonate can be problematic.

Sodium Carbonate study in Bulk-Flow’s research and development center in Barcelona

The study was conducted on a 1:10 scale, mirroring the circumstances of the Sodium Carbonate in repose after several days.

The angle of respose 90º which is the characteristic of an extremely cohesive bulk-solid product.

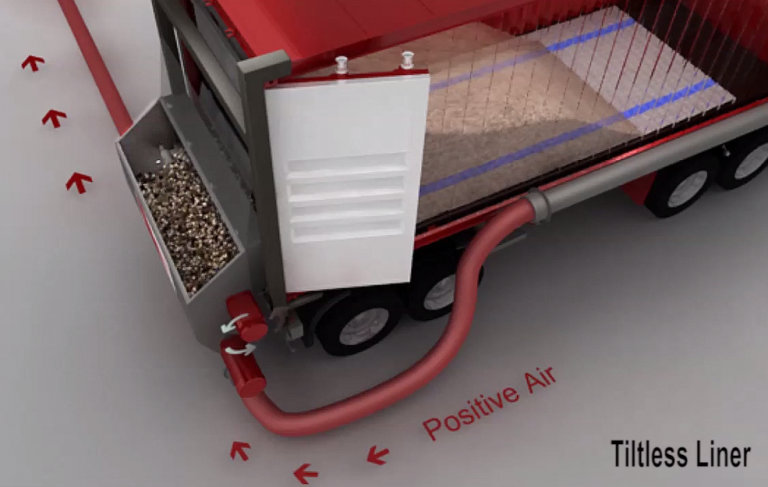

The unloading process used in the experiment is Bulk-Flow’s Tiltless Liner Horizontal. Unloading System together with pneumatic vibrating equipment.

Conclusion: Sodium Carbonate is a highly cohesive bulk-solid, which makes handling very complicated especially with systems that rely on gravity-unloading.

BULK-FLOW’s solution for the handling and transporting of sodium carbonate

As Sodium Carbonate is used for many different applications and industries, the logistics and handling aspects of its usage are highly important.

Bulk-Flow forwards the possibility of using standard 20’ DV containers with our Tiltless Liner, especially designed for low-density and high-density cohesive bulk-solids such as Sodium Carbonate.

Load, transport and unload in a completely safe and controlled protocol:

Closing the transport logistic circle and control the complete protocol with Bulk-Flow’s Tiltless Liner, which has been conceived to protect the bulk-solids from humidity from condensation in sea transport, as well as not needing expensive and scarce tilt container trucks.

The shipper and the consignee will be able to use standard sea containers for their bulk-solid transports making them very flexible and economic.